Mechanical

workings

Technology

and experience

at your service

Maifredi Francesco S.r.l. has been directly dealing with mechanical workings since 2010. The insourcing of this segment has made it possible to totally control the production process, thus guaranteeing customers a single interlocutor to get complete machine-bases from design to assembly.

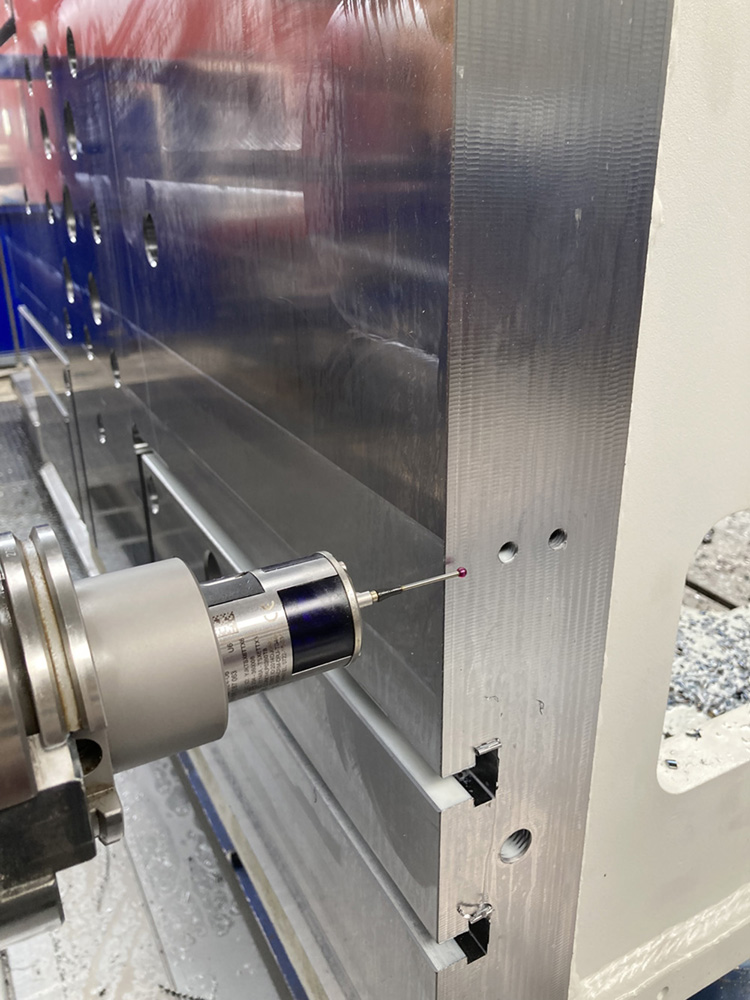

Controls are carried out through the Taylor-Hobson -collimator for linearity tolerances, while the Wyler-Niveltronic evaluates the perpendicular tolerances and the flatness.

In addition to mechanical processing, we also provide a painting service for some types of products.

Sectors

Maifredi Francesco S.r.l. carries out mechanical processes for several Italian and European companies, following the rigorous standards required by customers, thus pushing the company to steady updating and improvements.

The company’s customers operate in the most different industrial sectors:

presses for die-casting or cold forging

transfer-machines for medium- to large-sized components

machining centres for the automotive industry

moulds

air forces

Aerospace

Renewable energies (helical blades)

Structure for oversize-load-transports

Machine park

FPT – RONIN

Horizontal crosswise adjustment: X 12000 mm

Vertical spindle adjustment: Y 3000 mm

RAM stroke: Z 1500 mm

Head: head 0,001°

TOS – WHR 13 Q

Crosswise table adjustment: X 5000 mm

Vertical spindle adjustment: Y 3000 mm

Longitudinal colum adjustment: Z 2200 mm

Spindle stroke: W 700 mm

RAM stroke: V 650 mm

Max workpiece weight: Table 360° / 25 ton

Table size: Table 1800 X 2500

FPT – RONIN

Horizontal crosswise adjustment: X 12000 mm

Vertical spindle adjustment: Y 3000 mm

RAM stroke: Z 1500 mm

Head: head 0,001°

TOS – WHR 13 Q

Crosswise table adjustment: X 5000 mm

Vertical spindle adjustment: Y 3000 mm

Longitudinal colum adjustment: Z 2200 mm

Spindle stroke: W 700 mm

RAM stroke: V 650 mm

Max workpiece weight: Table 360° / 25 ton

Table size: Table 1800 X 2500